Mining in South Africa has been the main driving force behind the history & development of Africa’s most advanced & richest economy. Failure to embrace simple security sealing solutions to contain security breach, loss and damage is more often than not more costly to a mining operation than the cost of the implemented solution.

Mining operation threats

Theft, unauthorized access, vandalism & security compromise are daily threats across mining operations. Commonly, problems occur simply because internal controls are inadequate, the right products are not perceived to be available, and because the activity occurs undetected, usually over a period. If an organisation has no control measures in place and no reliable audit trail, would-be criminals would not be deterred in their activities and no recourse for action exists. There is no way of identifying the point of liability with accuracy and reliability. It needs to be identified whether the threat is an internal or external one, or collusion between the two.

Security that’s stood the test of time

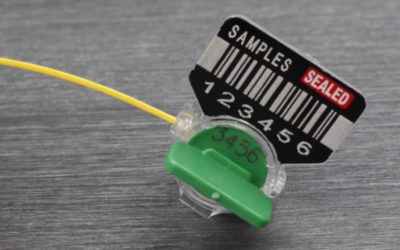

Without discounting the efficacy of other solutions, security seals and security packaging have measurably helped in reducing tampering and theft on mines throughout South Africa for decades.

Both under and above ground, mines need security seals for low-risk cost-sensitive items like safety equipment, (fire extinguishers and first aid boxes), right through to the protection of controlled high-security environments involving mining & extraction processes, explosives, confidential documents, ore and concentrate.

It is only through the correct usage that security seals can be effective in reducing tampering and theft. Thus, mining companies must be well-informed of their requirements during procurement, ensuring that appropriate solutions are purchased, which should be applied by authorised trained staff. Furthermore, after being applied security seals should be audited for proper compliance.

Risk management is a process

Although often a grudge purchase, the cost of the risk will always dwarf the cost of the solution. A frequently repeated mantra is re-iterated, “a seal is not a stand-alone solution but an integral part of a risk management process.”

Long standing relationships with blue chip players like Anglo Platinum, Lonmin, BHP Billiton, Anglo American Gold Ashanti, Petra Diamonds, Goldfields & De Beers, endorse that ‘we know our stuff’ but we cannot profess to be conversant with the detailed nuances of every problem or application or impact in your organization. Our comprehension of your unique challenges will enhance the worth of our recommendation.

EAM

Enterprise asset management (EAM) in a distributed asset network is an onerous task, but without a clear view of what assets you have, what condition they are in, what their optimum performance should be, who is interacting with these assets, what scheduled maintenance should take place and when these assets should be replaced, the business is exposed to imprudent spend and unjustified profit erosion.

We can help

Contact ICS today about doing a risk assessment on the business, executing an AIV (asset identification and verification) process, developing an AMIP (asset management improvement plan) with you, building an asset register based on industry best practice and growing with you to incorporate other EAM services such as facilities management, asset care, training, condition monitoring and consulting.

Select the mutual applications prevalent in this industry and review our recommended solutions.